HOW-TO: Cloud-Shared 3D Printing

Contents

Summary

As part of an experiment in shared 3D printing, I've made my Dremel 3D45 3D Printer publicly accessible to allow family, friends, and trusted users to upload, watch, queue, and print 3D print jobs to the Dremel PrintCloud.

In order to use our shared printer, you'll need the following:

- A Google Mail (Gmail) address for me to verify against

- To register or create an account using your Google Mail address on Dremel PrintCloud

- 3D Print Designs in the STL format, such as those available from Thingiverse

- Your mailing address so I can box up your Printed Jobs and mail them to you at the end of each week

If you want to get hold of me immediately/directly rather than e-mail, I'm always available via Discord on Tayledras |

HOW-TO

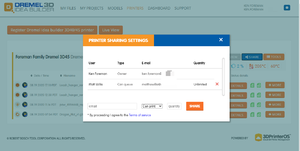

Getting an Account

To get an account on Dremel Print Cloud and to get access to our Dremel 3D45 printer:

- Register an account using your Google account to Dremel Web Services

- E-mail, Google Talk, or Discord me at [email protected]

- I'll need to know your name and mailing address if you would like me to send you your print jobs each week. 😁✌

3D Printer Software (Designing/Editing/Modeling/Slicing)

None of these are necessary if you're content to use the web-based Dremel PrintCloud to upload, access, and print. These are all very useful if you want to design, edit, or do higher-precision work locally (on your PC) rather than on the Cloud:

- Free Dremel Digilab 3D Slicer available for Windows and Mac.

- Free/Licensed Ultimaker Cura available for Windows and Mac.

- Free/Paid Sketchup 2020 available for Web, Windows, Mac.

- Paid Simplify3D available for Windows and Mac.

3D Printer Permissions

Once you have a Dremel Cloud Account, you'll be able to:

- Upload, Edit, Repair, Layout, Slice using Dremel - My Files

- Upload, Edit, Repair, Layout, Slice using Dremel - My Projects

- LiveView, Queue using Dremel - My Printers

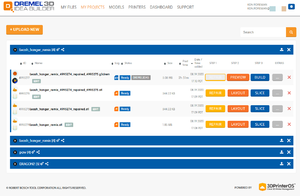

Using Dremel 3D Cloud Projects

Step 1: Repair

REPAIR allows Dremel to verify it's a clean, logical, and actually printable 3D design. Any issues like impossible geometries or design errors should be caught and fixed during the Repair or you will be warned that this Design is not actually something that can be physically printed using a filament printer.

Step 2: Layout

LAYOUT allows you to visualize, move, rotate, and edit how the Design will be printed. Remember that you are printing using soft ABS, PLA, and Nylon filaments that are soft when printed and quickly hardens as the extruder head moves. Anything that is top-heavy will warp, distort, or fall before the plastic hardens, so you want the heaviest parts near the bottom and the lightest parts at top, or you will need to use RAFTS and SUPPORTS to hold your pieces in place (in 3D space). RAFTS and SUPPORTS are pieces you will need to CUT, TRIM, or REMOVE yourself after you get your printed design.

Step 3: Slice

SLICE allows Dremel to convert a Computer Aided Design (CAD) vector drawing from a 3D plot to a layer-by-layer set of instructions that the 3D printer can understand. Think of it as the slices of an MRI or CT scan. While the finished project is 3D, the printer needs a set of 2D layer-by-layer instructions (slices) to build the 3D object from. Enable RAFTS but disable SUPPORTS unless you know what you are doing and you need them to hold your pieces in place (in 3D space). RAFTS and SUPPORTS are pieces you will need to CUT, TRIM, or REMOVE yourself after you get your printed design.

Enable RAFTS but disable SUPPORTS unless you are positive you know how to use them, trim them, and why. |

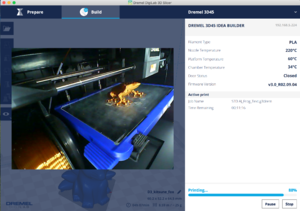

Step 4: Build

BUILD allows Me to add your print job to my Print Queue. I will need to know the following before I print your design:

- What color do you want? (Any color of opaque, translucent, or metallic)

- What type do you want? (ABS, ECO-ABS, PLA, Nylon)

- What style do you want? (Opaque, Translucent/Clear, Metallic, Thermal)

Metallic print jobs use "Shiny Silk" PLA filaments that look like Copper, Brass, Bronze, Silver, Gold, Aluminum, Titanium, and can be found if you search Amazon for "Shiny Silk, Metallic, PLA filaments"

Thermal print jobs use thermally-responsive PLA filaments that are color-changing (Purple>Blue>Pink, Green>Gold>Yellow, Orange>Yellow) when exposed to changes in temperature.

Understanding Plastics

Reference:

Summary:

PLA, ABS, and nylon are three of the most popular 3D printing materials. All can be extruded on basic 3D printers and, at around $20 per spool, they are among the most affordable filaments available today. Most people focus on the PLA vs ABS debate, but Nylon is a valuable third entrant with different material properties.

PLA and ABS are both thermoplastics. PLA is stronger and stiffer than ABS, but poor heat-resistance properties means PLA is mostly a hobbyist material. ABS is weaker and less rigid, but also tougher and lighter, making it a better plastic for prototyping applications.

PLA Plastic

PLA is a user-friendly thermoplastic with a higher strength and stiffness than both ABS and nylon. With a low melting temperature and minimal warping, PLA is one of the easiest materials to 3D print successfully. Unfortunately, its low melting point also causes it to lose virtually all stiffness and strength at temperatures above 50 degrees Celsius. In addition, PLA is brittle, leading to parts with poor durability and impact resistance.

Although PLA is the strongest of these three plastics, its poor chemical and heat resistance force it into almost exclusively hobbyist applications.

Shiny Silk PLA Filaments are "beast unto themselves", see HOW-TO: 3D Printing with Shiny Silk PLA Filaments for more details. |

ABS Plastic

ABS, while weaker and less rigid than PLA, is a tougher, lighter filament more suitable for some applications beyond purely hobbyist. ABS is a bit more durable, is about 25% lighter, and has four times higher impact resistance. ABS does require more effort to print than PLA because it’s more heat resistant and prone to warping. This calls for a heated bed and an extruder that is 40-50 degrees Celsius hotter. ABS, while by no means a heat resistant plastic, has superior heat deflection temperature compared to PLA and nylon.

The improved durability over PLA lends ABS to some more practical applications, such as prototyping and low-stress end-use parts.

Nylon

Nylon is a flexible, durable plastic with less strength and stiffness than both PLA and ABS. Its malleability lends it much more toughness than the other two, however, with an impact resistance ten times that of ABS. Nylon also boasts a good chemical resistance, which opens the possibility to more industrial applications. As with ABS, nylon requires extra care to print; it needs to be extruded at high temperatures and, due to its tendency to soak up moisture from the air, must be kept in a dry box.

Nylon is tougher and more resistant to chemicals than ABS and PLA, but its low strength and stiffness keep it from being widely used in the manufacturing industry. As a result, advancements in 3D printing materials has introduced nylon-fiber mixtures, opening the door to accessible industrial 3D printing.

Nylon is a synthetic polymer which is based on polyamides. It’s resilient, strong, durable and a tad bit flexible. Another property is that it’s hydroscopic. This means it absorbs liquids. This makes nylon a good choice when you need to dye your printed part in a certain color. It also means that nylon filament has a short shelf live and is difficult to store.

Since nylon has such a unique durability to flexibility ratio, it is often used for functional parts. Think of prosthetics, medical equipment, connectors and living hinges.

References:

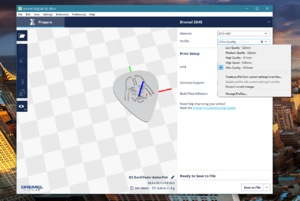

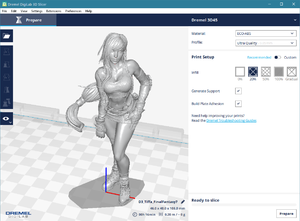

ADVANCED: Ultra Quality (0.05mm) Resolution Printing

This is MUCH slower to print (3-4x slower) but MUCH higher detailed than what the Dremel web editor allows. It also takes a little more skill than the "just Web" user interface. |

- Download Dremel Digilab 3D Slicer available for Windows and Mac.

- Install Dremel Digilab 3D Slicer on your PC

- Configure for "Dremel Digilab 3D45" printer

- Open File | <name-of-local-STL-you-wish-to-edit>

- Configure Material for "ECO-ABS"

- Configure Profile to "Ultra Quality (0.05mm)"

- Save As File, save gCode file locally to your PC

- Upload your local gCode file to Dremel - My Files and proceed with Layout and Slice (as you normally would via the web UI)

EXAMPLES and SAMPLES

- As I print things, I'll occasionally (and hopefully more often) upload them to Thingiverse - Ken Foreman's Makes

- I'm experimenting in 3D scans and my own designs as Thingiverse - Ken Foreman's Designs

- As I experiment with optimal temperatures, resolutions, and filament materials, I'll take nodes and update NOTES: Improving Upon 3D Printing